-Sufficient BHS capacity as defined in the UCD to

support the Airport passenger traffic of 60 MAP

-Cost effective to implement

-Operationally and energy efficient to meet

AOT’s baggage KPIs and service standards

-Resilient, including redundancy to be in line with

IATA standards and International best practices

-Utilise proven state-of-the-art technologies to

minimize risk to the airport

-Space in existing MTB baggage handling area

-Modifying BHS in existing MTB under operational conditions

-Budget for BHS

-60 minute MCT

-Interface to existing IT systems (AODB, CUTE, FIDS, etc.)

-Outbound Bags from MTB to SAT-1

-Transported using BHS transport system in tunnel

-Arrival Bags from SAT-1 to MTB

-Transported using tug & dolly

-To consider alternate transport methods using BHS

-Inter-Terminal Transfer Bags

-4 Concepts

-Via BHS equipment in tunnel, or

-Using tug & dolly by apron roads

between MTB and SAT-1

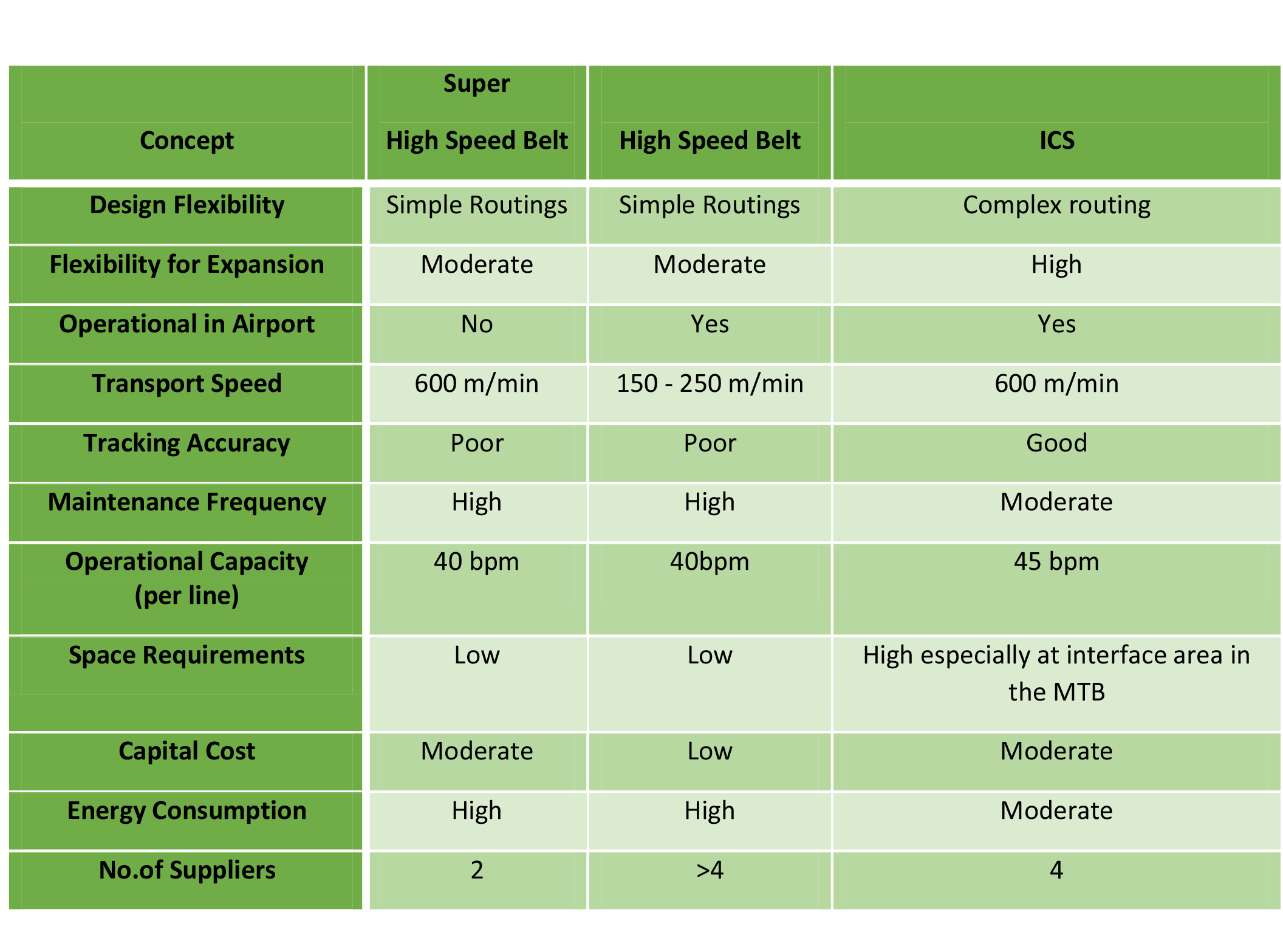

Technology 1

-Super High Speed Conveyor at 600 m/min

-Key Concern: Currently not installed in any airport

-Technology 2

-High Speed Conveyor at 150-250 m/min

-Key Concern: Speed is slower

-Example: Kuala Lumpur, Cincinnatti, Pittsburgh, Madrid and Incheon for inbound bags

-Technology 3

-Individual Carrier System (ICS, High Speed Tray) at 600 m/min

-Key Concern:

-Space in existing MTB for existing BHS/ICS interface

-Cost

-Example: Beijing T3, Incheon, Singapore, Munich, Madrid, Heathrow T5, Schiphol, etc

For Concepts using High Speed Conveyor to transport bags between MTB and SAT-1

Concept 1

-Sortation at SAT-1: Tilt-tray or Cross Belt sorting system

-Capacity: 80 bpm per sorter

Concept 2

-Sortation at SAT-1: Belt sorting system

-Capacity: 30 bpm per sort conveyor line

-For Concepts using Individual Carrier System to transport bags between MTB and SAT-1

Concept 3

-Sortation at SAT-1: Individual Carrier System

-Capacity: 45 bpm per ICS line