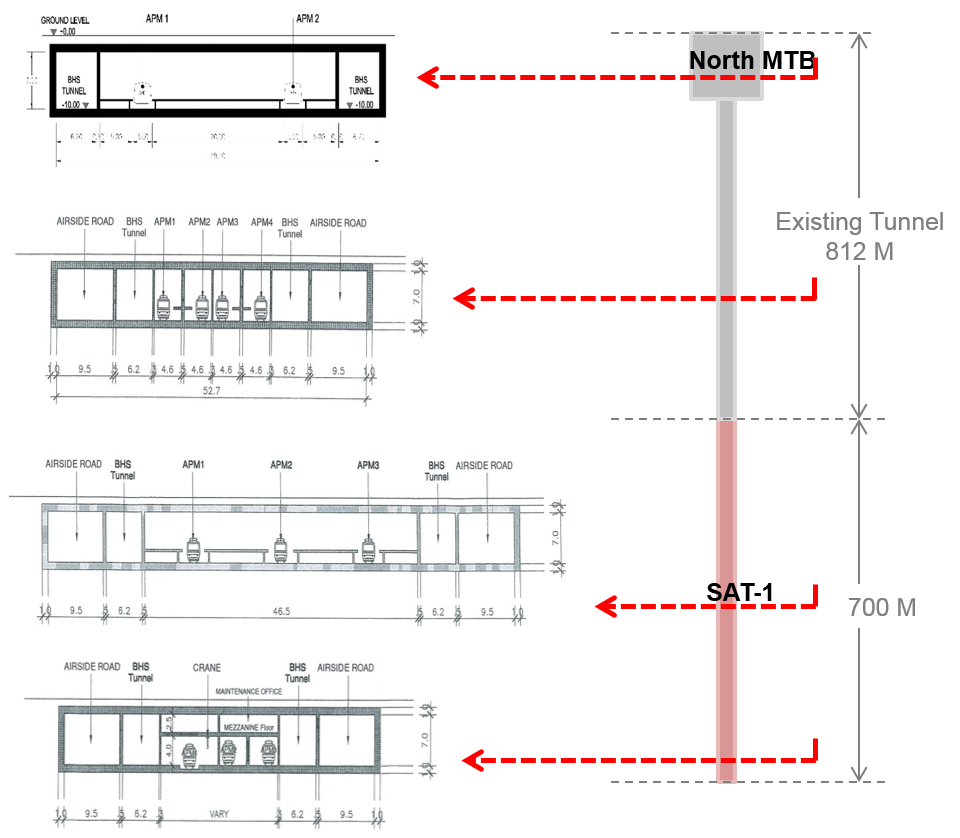

• SAT-1 will be built south to NMTB.

• Automated People Mover will be the only transportation of passenger among two terminals.

-Fully automated & driverless transit system

-Exclusive right of way / guideway

-Tunnel in BKK

-Proprietary system by each supplier – not interchangeable

-Performance Specifications are the Industry Standard for procuring APM systems

-Varying system characteristics & facility design

-Best addressed by early procurement of the APM

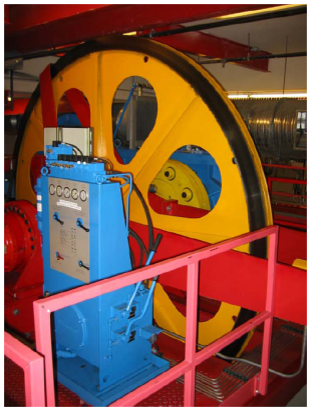

-Cable Propelled (no on-vehicle motors)

-Cable under car, in guideway

-10 - 120 passengers / vehicle

-Passive vehicle (only housekeeping electrical)

-Rubber tire, steel wheel or air-levitated §Elevated, at-grade or tunnel

-Requires rooms for drive & return sheaves

-Can be inside a building (DTW & NDIA)

-Detachable grip & switches now available

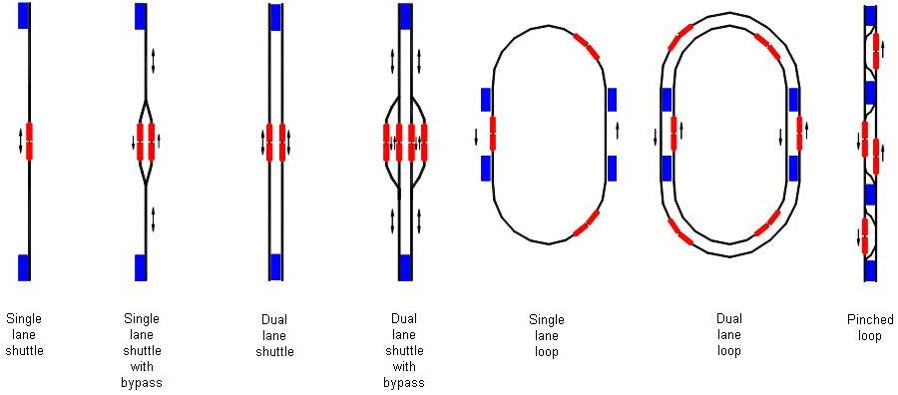

-Historically: short shuttles (~ 1 km)

-Now: up to 5 km / pinched loops possible

-Electrically self-propelled (traction motors or LIM)

-Rubber tire, steel wheel- steel rail, maglev

-Bottom supported

-Center or Side Guidance Systems

-Elevated, at-grade, in tunnel §Various switch types

-40 - 130 passengers / vehicle 1 – 6 cars / train

-Easiest for system expansion

-Most Typical Airport APM for loop or pinched loop configurations

-Each has implications for:

-Routing complexity

-System Types (cable or self propelled)

-Networking

-Expandability

-Require Coordination with Fixed Facilities Designers:

-Guideway/Tunnel

-Running Surface (plinth), Guidance & Switching, and Emergency Walkway typically by APM supplier

Stations

-Adjacent Equipment Room

-Maintenance & Storage Facility (MSF) (or depot)

-Central Control (OCC)

-Adjacent Equipment Room

-Adjacent UPS

-Power Distribution Substations (PDS) DC or AC

-Project / System Requirements – Established by UCD

-System Configuration and General Alignment(s) - initial & future

-Service levels - trip times, hours / day, availability 99.5% +

- Ridership Demand - initial & future

- Define applicable type(s) of technologies

-Confirm APM capacity accommodates passenger demand(s)

-Preliminary Design and Detailed Design

-Coordinate Requirements/Interfaces with Fixed Facilities

-Develop performance specifications contract documents

-Reference Drawings by Fixed Facilities Designers

-APM System Competitive Procurement Process to Select Supplier

-Performance Specifications

-DB or DBOM

-Fixed Facilities Procurement by Other Contract(s)

-Conventional procurement (public low bid)

-Submission and Review of APM Supplier’s Design Submittals

-In-Plant Manufacturing and Observation

-On-Site Installation and Observation

-Acceptance Testing

-Vehicle/Wayside Testing

-System Level Testing

-System Demonstration

-Safety Certification and Start of Revenue Service/Warranty Period

-O&M Commences

-Competition ensures best value to Owner

-Performance Specifications allow competition and innovation between multiple APM

suppliers and are the Industry Standard

-The Procurement Process must ensure only Service-Proven Technologies

-In Order to Achieve Seamless Future Expansion:

-Expansion by original supplier is almost universal

-Expansion by third party supplier is problematic

-Fast-Tracking APM procurement ahead of fixed facilities helps coordination and interface